How to choose dry ice cleaning equipment correctly?

- Posted by OLLITAL

- Date 2024-06-19

Eight advantages of dry ice cleaning: How to choose dry ice cleaning equipment correctly?

June 19, 2024

Dry ice cleaning is also known as dry ice blasting. In the field of industrial cleaning, dry ice blasting cleaning technology has become the first choice of many companies due to its environmental protection, efficiency and versatility. Dry ice blasting can not only thoroughly remove various dirt, but also protect the cleaning object from damage. So, what are the unique advantages of dry ice blasting? How should enterprises correctly choose dry ice blasting equipment? This article will give you a detailed answer.

What is Dry Ice Cleaning?

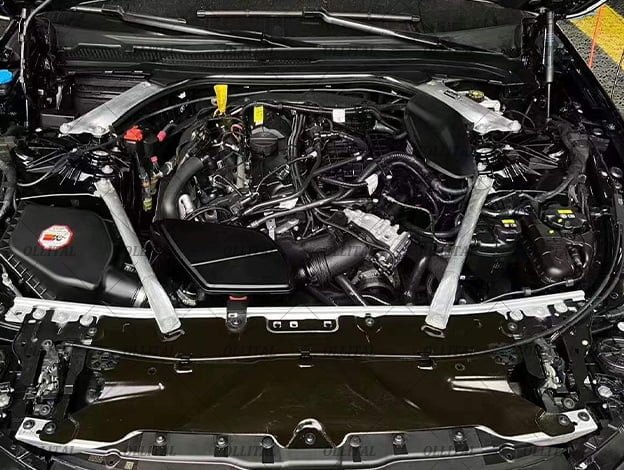

In the field of modern cleaning technology, dry ice blasting has become an innovative method that has attracted much attention.[Dry Ice Blast Demonstration Guide] This cleaning technology uses solid carbon dioxide (dry ice) particles to blast surfaces through high-speed airflow to remove dirt, oil, and other surface contaminants. Compared with traditional cleaning methods, dry ice blasting has unique advantages in terms of environmental protection and non-abrasiveness.

Dry ice abrasive blasting is a cleaning and cooling technology that uses solid carbon dioxide (CO2), or dry ice. Dry ice is the solidification of carbon dioxide under high pressure conditions, with a very low temperature of about minus 78.5 degrees Celsius (minus 109.3 degrees Fahrenheit). Due to its low temperature and special properties, dry ice is used in a variety of applications, including dry ice abrasive blasting.[Dry Ice Production Demonstration Guide]

During the blasting dry ice process, solid carbon dioxide is discharged from special equipment at high speed. Dirt, grease, pollutants, etc. are completely removed from the surface through the force and temperature effect of the spray. This process is widely used in industrial cleaning, equipment maintenance, food processing equipment cleaning, and more. Because dry ice leaves no residue during the cleaning process and produces no waste other than carbon dioxide, it is considered an environmentally friendly cleaning technology.

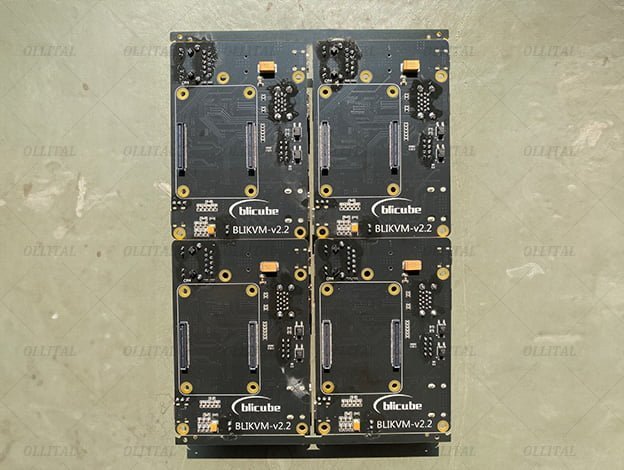

In addition, because dry ice quickly sublimates into gas after spraying and does not produce liquid waste, blasting dry ice is also used in some water-sensitive applications, such as electronic equipment maintenance, electrical equipment cleaning, etc. This technology is also widely used in some special cleaning occasions, such as hygienic sensitive areas, food production lines, etc.

Eight advantages of dry ice cleaning

1. No residue

Dry ice cleaning uses solid carbon dioxide particles, which are directly sublimated into gas after cleaning, leaving no solid residue. This means that no secondary cleaning is required after cleaning, which greatly saves time and labor costs.

2. Environmental protection

Dry ice is directly condensed from carbon dioxide gas. Using dry ice cleaning does not require any chemical solvents and is environmentally friendly. No harmful wastewater or exhaust gas will be generated during the cleaning process, which meets the high environmental protection requirements of modern enterprises.

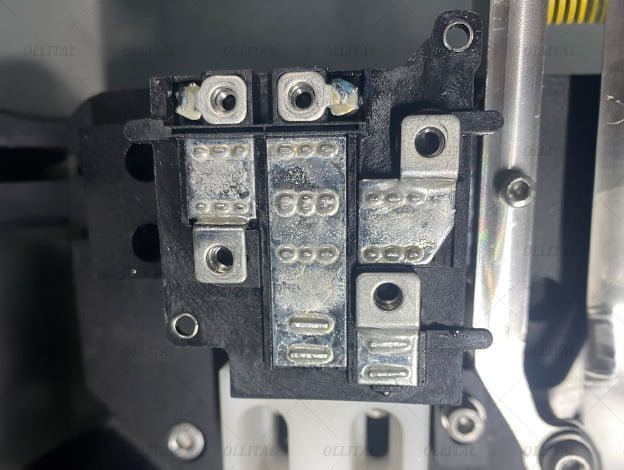

3. Non-conductive

Dry ice particles are non-conductive and are particularly suitable for cleaning electrical equipment and electronic components. Using dry ice cleaning can avoid short circuits and other electrical failures and ensure the safe operation of equipment.

4. Gentle and non-destructive

During the dry ice cleaning process, the temperature of the dry ice particles is extremely low, which can effectively remove dirt without damaging the surface being cleaned. It is particularly suitable for cleaning precision equipment and sensitive materials to ensure the integrity and service life of the equipment.

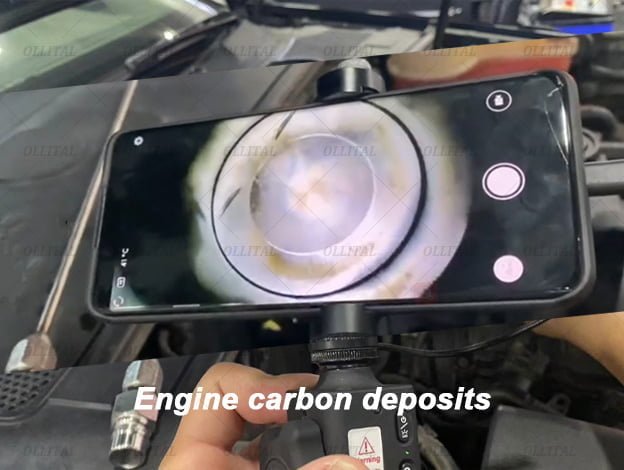

5. Efficient decontamination

Dry ice cleaning uses high-speed particle impact and thermal shock effects to quickly and thoroughly remove stubborn dirt such as grease, paint, and resin. Compared with traditional cleaning methods, dry ice cleaning is more efficient and effective.

6. Reduce downtime

Due to the fast speed and no residue of dry ice cleaning, the equipment can be resumed immediately after cleaning, which significantly reduces production downtime and improves production efficiency.

7. Wide range of applications

Dry ice cleaning is suitable for equipment and surfaces of various materials and shapes, whether metal, plastic or composite materials, whether flat, grooved or complex shapes, it can achieve good results.

8. Reduce manual operation

Modern dry ice cleaning equipment usually has a high degree of automation, and only a small amount of manual operation is required to complete complex cleaning tasks, reducing labor costs and operational risks.

Eight major disadvantages of dry ice cleaning

1. High cost

Dry ice has high production and transportation costs, especially for cleaning tasks that require a large amount of dry ice. In addition, the initial equipment investment is also large, which may be a burden for small businesses.

2. Complex operation

Dry ice cleaning equipment on the market requires professional operators to operate and maintain, and has high requirements for personnel training. Incorrect operation may cause equipment damage or poor cleaning effect.

3. Equipment maintenance

Dry ice cleaning equipment on the market requires regular maintenance and overhaul, and the maintenance cost is high. At the same time, the vulnerable parts of the equipment need to be replaced frequently, which increases operating costs.

4. Noise problem

The noise generated during dry ice cleaning is large, which may affect the operator and the surrounding environment. Therefore, it is necessary to operate in an environment with good sound insulation.

5. Safety risks

Dry ice cleaning involves high pressure and low temperature operations, which poses certain safety risks. Improper operation may cause frostbite or equipment damage, and special attention should be paid to safety protection.

6. Limited scope of application

Although dry ice cleaning is suitable for a variety of materials and shapes, the cleaning effect may not be ideal for some particularly hard or highly adherent dirt. At this time, it may be necessary to use it in conjunction with other cleaning methods.

7. Difficulty in Dry Ice Storage

Dry ice sublimates quickly at room temperature and has a short storage time, requiring special low-temperature storage equipment. This increases logistics and storage costs and is not conducive to long-term storage.

8. Waste gas emissions

Although there is no solid waste during dry ice cleaning, the emission of carbon dioxide is relatively large. When used in a closed environment, good ventilation equipment is required to prevent excessive carbon dioxide concentration from affecting the health of operators.

How to choose dry ice cleaning equipment correctly?

Choosing the right dry ice cleaning equipment is crucial to the cleaning efficiency and effect of the company. When choosing equipment, companies should consider the following key factors:

1. Production needs

First, clarify your production needs and cleaning objects. Different types of dry ice cleaning equipment are suitable for different application scenarios, such as electronic equipment cleaning, heavy industrial cleaning, etc. Understand your specific needs and choose the most suitable type of equipment.

2. Equipment performance

Pay attention to the performance indicators of the equipment such as cleaning efficiency, particle injection speed, and pressure range. High-performance equipment can significantly improve the cleaning effect and efficiency and ensure the efficient completion of cleaning tasks.

3. Degree of automation

Choosing equipment with a high degree of automation can reduce manual operation and improve the stability and safety of the cleaning process. Modern equipment is usually equipped with intelligent control systems that can achieve automatic adjustment and monitoring.

4. Equipment quality and reliability

The manufacturing materials and processes of high-quality equipment determine its durability and reliability. Choose brands and suppliers with good reputation and after-sales service to ensure the stable performance and low failure rate of the equipment in long-term use.

5. Energy consumption

The energy consumption of dry ice cleaning equipment directly affects the operating cost. Choosing equipment with high energy efficiency can not only reduce operating costs, but also reduce carbon emissions and meet environmental protection requirements.

6. Safety

Dry ice cleaning involves high pressure and low temperature operations, so the safety of the equipment is particularly important. Choose equipment with multiple safety protection functions, such as automatic shutdown, pressure release and other functions to ensure the safety of operators and equipment.

7. After-sales service

It is very important to choose a supplier that provides comprehensive after-sales service. Good after-sales service includes equipment installation and commissioning, operation training, regular maintenance and fault repair to ensure that the equipment is always in the best operating condition.

8. Cost-effectiveness

Consider the purchase cost, operation cost and maintenance cost of the equipment and choose the most cost-effective equipment. Although the initial investment of high-quality equipment is higher, its high efficiency, stable performance and low maintenance cost can bring higher economic benefits in long-term use.

Our dry ice cleaning equipment

Our dry ice cleaning equipment is committed to overcoming the traditional shortcomings of dry ice cleaning and providing efficient, reliable and safe cleaning solutions. The unique advantages of our products include:

1. Cost-effectiveness

We offer a variety of models of dry ice cleaning equipment to meet the needs of enterprises of different sizes. Whether it is a small factory or a large industrial enterprise, you can find the right equipment to help you find the best balance between initial investment and long-term operating costs.

2. Easy to operate

Our equipment design focuses on user experience, and the operation interface is simple and intuitive, easy to use. Even first-time operators can quickly master the operating skills after simple training to ensure the cleaning effect.

3. Low maintenance requirements

We use high-quality materials and advanced manufacturing processes to ensure the durability and reliability of the equipment. The equipment has a long maintenance cycle and easy replacement of vulnerable parts, which reduces downtime and maintenance costs.

4. Noise control

Through optimized design, our equipment has lower noise during operation, reduces the impact on operators and the surrounding environment, and improves the comfort of the working environment.

5. Complete safety measures

Our equipment is equipped with multiple safety protection functions, including automatic shutdown, pressure release, antifreeze gloves and masks, etc., to ensure the safety of operators and the stable operation of equipment.

6. Efficient storage and transportation

We provide professional dry ice storage and transportation solutions to ensure the stability and long-term effectiveness of dry ice during storage and transportation, reducing logistics and storage costs.

7. Environmentally friendly design

Our equipment meets strict environmental standards, reduces carbon dioxide emissions, and is equipped with advanced ventilation and exhaust gas treatment systems to ensure the health and safety of operators.

Act now!

Choosing our dry ice cleaning equipment, you will enjoy the most advanced cleaning technology and comprehensive after-sales service, helping your company improve cleaning efficiency, reduce costs, and improve environmental standards.

Contact us to learn more about dry ice cleaning equipment and seize the opportunity to improve production efficiency and environmental standards!

START OWNING THIS TECHNOLOGY NOW !

Contact us today to learn more about our solutions.

You may also like

What is dry ice manufacturing? How is dry ice produced?