Dry Ice Blasting VS Traditional Cleaning: Which is Right for Your Project?

June 14, 2024

In the field of industrial cleaning, choosing the right cleaning method is crucial to the efficiency, cost and environmental protection requirements of the enterprise. In recent years, dry ice cleaning technology has rapidly emerged due to its unique advantages, forming a sharp contrast with traditional cleaning methods. So, which one is more suitable for your company, dry ice cleaning or traditional cleaning methods? This article will make an in-depth comparison of the two cleaning methods to help you make a wise choice.

Introduction to dry ice cleaning

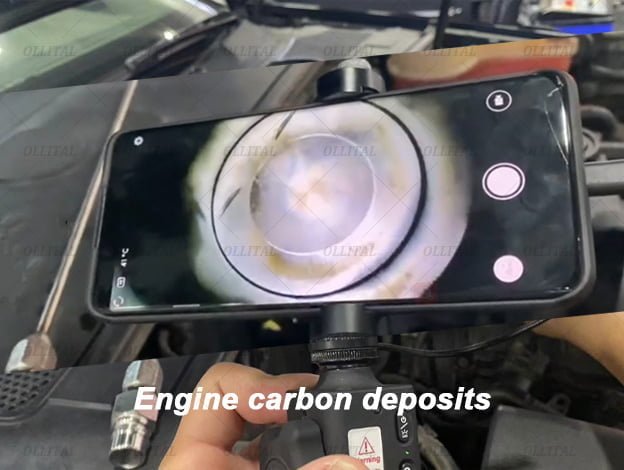

Dry ice cleaning uses solid carbon dioxide (i.e. dry ice) particles, which are sprayed onto the surface to be cleaned by a high-pressure gas stream. The dry ice particles quickly sublime into a gas upon impact with the surface, using thermal shock and mechanical force to remove dirt.

Advantages of dry ice cleaning

No residue: Dry ice sublimates into carbon dioxide gas during the cleaning process, leaving no residue and avoiding secondary pollution.

Environmentally friendly: No chemical solvents are used, which is environmentally friendly. Dry ice itself is extracted from industrial byproduct carbon dioxide, reducing carbon emissions.

Non-conductive: Suitable for cleaning electrical equipment and electronic components, avoiding the risk of short circuits and damage.

Gentle: It will not damage the surface to be cleaned and is suitable for cleaning delicate and sensitive equipment.

Efficient: Dry ice cleaning can quickly remove stubborn dirt such as grease, paint and resin.

Disadvantages of dry ice cleaning

High cost: Dry ice production and transportation costs are high, and the initial equipment investment is large.

Complex operation: Professional operators are required for operation and maintenance.

Limited scope of application: Not suitable for cleaning large surfaces or very strong attachments.

Introduction to Traditional Cleaning Methods

Traditional cleaning methods include ultrasonic cleaning, high-pressure water jet cleaning, chemical cleaning and mechanical cleaning, etc. Each of these methods has its own scope of application and characteristics.

Ultrasonic cleaning

Advantages:

Efficient cleaning: Suitable for complex shapes and small parts.

Gentle: Will not cause mechanical damage to the surface.

Disadvantages:

High equipment cost: Large initial investment.

Limited scope of application: Not suitable for large surface areas.

High-pressure water jet cleaning

Advantages:

Efficient decontamination: Quickly remove stubborn dirt.

Versatile: Suitable for various equipment and pipelines.

Disadvantages:

High water consumption: Not suitable for areas with water shortage.

Possible surface damage: High-pressure water flow may damage fragile surfaces.

Chemical cleaning

Advantages:

Deep cleaning: Effectively remove internal deposits.

Quick: Fast cleaning speed.

Disadvantages:

Chemical residue: There may be chemical residue.

Environmental impact: Some chemical agents are polluting to the environment.

Mechanical cleaning

Advantages:

Direct and effective: Suitable for solid dirt and large area cleaning.

Easy to use: No complex equipment is required.

Disadvantages:

Damage to the surface: Mechanical force may damage the surface of the equipment.

Labor-intensive: Requires a lot of manpower and low efficiency.

Dry ice cleaning vs. traditional cleaning methods: Which is better for your project?

Environmental friendliness

Dry ice cleaning has no chemical residues and is environmentally friendly, especially suitable for companies with high environmental requirements. Traditional chemical cleaning may cause environmental pollution problems and require special treatment of waste liquid.

Cost considerations

The initial investment in dry ice cleaning equipment is high, but the long-term use cost may be low, especially when cleaning is frequent and efficiency requirements are high. Among traditional cleaning methods, mechanical cleaning and high-pressure water jets have lower initial investments, but the long-term costs of chemicals and water resources cannot be ignored.

Cleaning effect

Dry ice cleaning is effective in cleaning complex, precise and sensitive equipment, while high-pressure water jets and mechanical cleaning are more effective in dealing with large areas and solid dirt. Ultrasonic cleaning is suitable for small precision parts, but not for large-scale applications.

Safety

Dry ice cleaning has no chemical residues and secondary pollution, and is suitable for industries with high safety requirements such as food processing and pharmaceuticals. Traditional cleaning methods require safety protection in chemical treatment and high-pressure water flow operations.

Operation difficulty

Dry ice cleaning equipment requires professional training and maintenance [Dry Ice Blast Demonstration Guide], but the operation interface is designed to be user-friendly and easy to master. Among traditional cleaning methods, mechanical and high-pressure water jet operations are relatively simple, but chemical cleaning requires professional knowledge.

Conclusion

Choosing the right cleaning method depends on your specific needs and application scenarios. Dry ice cleaning technology is particularly suitable for companies with high requirements for environmental protection and cleaning accuracy due to its residue-free, environmentally friendly and efficient characteristics. Traditional cleaning methods have their unique advantages in cost control and large-area cleaning.

Recommend our dry ice cleaning equipment

If your company needs efficient, environmentally friendly and safe cleaning solutions, our dry ice cleaning equipment is your best choice. We provide high-quality equipment, comprehensive technical support and excellent after-sales service to ensure that your cleaning tasks are completed efficiently.

Contact us now to enjoy a limited-time offer and improve your cleaning efficiency and environmental standards!

In addition, if you have the need to produce dry ice pellets yourself, our dry ice pellet production machine also provides you with efficient and economical solutions to help you significantly reduce production costs.

Act now!

Don’t miss this opportunity, contact us to learn more about our dry ice blasting equipment and dry ice pellet production machines, and take your business into a new era of efficient blasting!

START OWNING THIS TECHNOLOGY NOW !

Contact us today to learn more about our solutions.