Dry Ice Blast Demonstration Guide

July 10, 2023

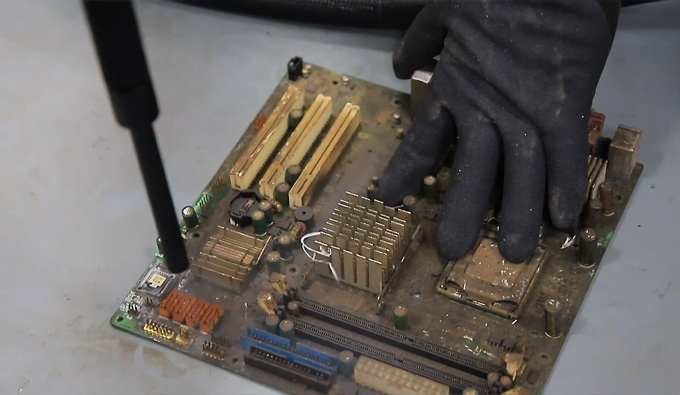

Dry ice blasting is a surface treatment method that uses solid carbon dioxide (i.e. dry ice) as a cleaning agent. This technology is not only environmentally friendly, but also highly efficient and leaves no secondary pollution. The following is a detailed demonstration guide to dry ice blasting designed to provide a comprehensive guide to those who want to learn about or use this technology.

Dry ice blasting technology overview

Dry ice blasting is a non-abrasive cleaning technology that uses dry ice particles to impact surfaces at high speeds to remove dirt, grease or other contaminants from the surface. Dry ice particles instantly change from solid to gaseous state when they hit a surface, a process called sublimation. This transformation provides tremendous surface cleaning capabilities as the dramatic expansion of volume during sublimation helps loosen and remove dirt.

Equipment and material preparation

Dry ice blasting machine: Choose a dry ice blasting machine that suits your needs. Important parameters include blasting pressure, dry ice consumption rate, etc.

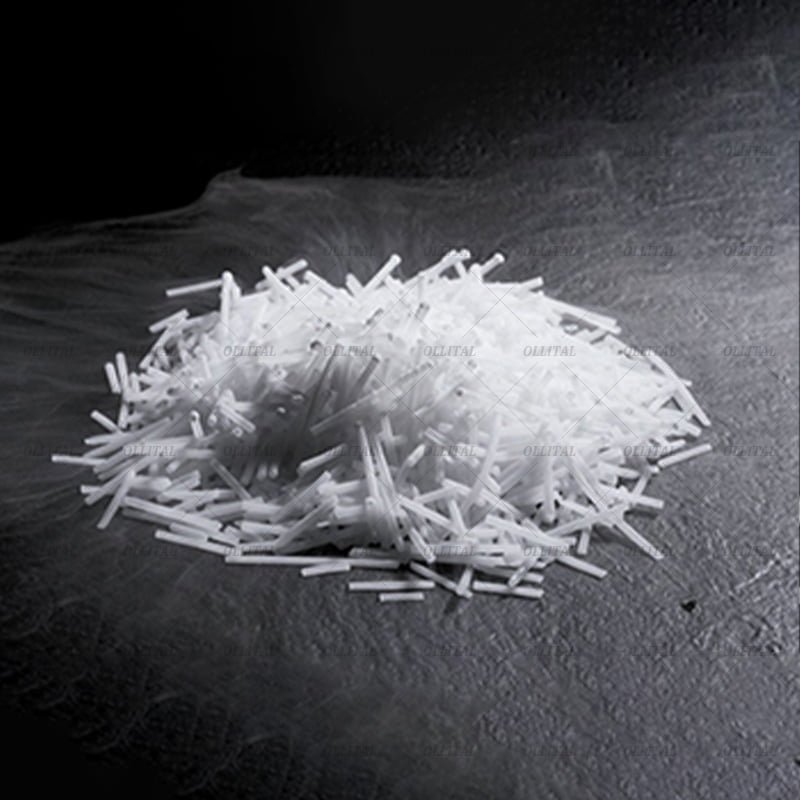

Dry ice pellets: Usually the diameter of dry ice pellets is between 3mm and 16mm.

Safety equipment: including protective glasses, earplugs, protective gloves, dust masks, etc.

Preparing the Cleaning Area: Make sure the work area is well ventilated to handle sublimated carbon dioxide gas.

Operation steps

Check the equipment: Make sure all parts of the dry ice blaster are installed correctly and are not worn or damaged.

Fill with dry ice: Fill with the appropriate amount of dry ice pellets according to the device’s instructions.

Safety: Wear all necessary safety equipment.

Start the equipment: Turn on the dry ice blasting machine and adjust to the appropriate blasting pressure.

Blast Cleaning: Use a dry ice blaster to spray the target surface evenly. Keep the spray gun perpendicular to the surface when spraying, about 10 to 15 centimeters away.

Evaluate the cleaning effect: After cleaning, check whether the surface has been cleaned as expected. If necessary, the blasting process can be repeated.

Precautions

Safety first: Since dry ice is very cold (-78.5°C), direct contact may cause frostbite.

Ventilation: Because dry ice sublimates into carbon dioxide gas, it is important to ensure that the working environment is well ventilated to prevent accumulation of gas that may lead to suffocation.

Equipment maintenance: Check injection equipment regularly to ensure all connections are tight to avoid gas leaks.

Conclusion

Dry ice blasting is an efficient and environmentally friendly cleaning technology that is ideal for a variety of applications that require quick, thorough cleaning without leaving residue. By following the guidelines above, you can use dry ice blasting safely and effectively, keeping your equipment and work environment clean and safe. Correct operation and maintenance can not only improve cleaning efficiency, but also extend the service life of equipment and ensure safe production. Hopefully this demonstration guide to dry ice blasting will help you better understand and use this technology. If you have any questions or need professional guidance during use, it is recommended to contact our service team for further support.

START OWNING THIS TECHNOLOGY NOW !

Contact us today to learn more about our solutions.