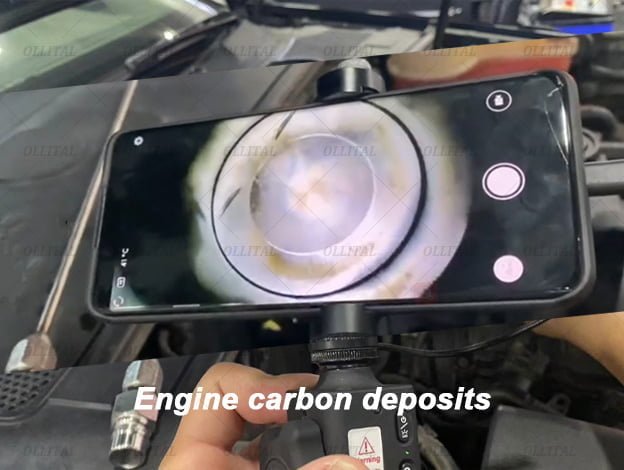

Dry Ice Blasting Cleaning

- Home

- Dry ice blasting cleaning

Dry ice blasting cleaning solutions

Dry Ice blasting cleaning is a method of surface cleaning and dirt removal using dry ice particles (carbon dioxide solid). This technology is commonly used to clean equipment, machine parts, industrial facilities and other surfaces. It works by colliding high-speed jets of dry ice particles with dirt on the surface being cleaned, causing the dirt to freeze and fall off. Because dry ice will be converted directly into gas after spraying, it will not leave any residue, which makes dry ice cleaning technology particularly suitable for food equipment, electronic equipment and other occasions that have strict residue requirements. Additionally, since water is not required during dry ice cleaning, electrical hazards and equipment damage caused by liquids are avoided.

OLLITAL specializes in the R&D, production, sales and service of dry ice blasting, dry ice production, dry ice transportation and other one-stop service-related supporting equipment. Our efficient, environmentally friendly, safe and flexible cleaning equipment has won a good reputation in the industry and has been sold to many countries around the world. As labor management costs and land costs continue to increase, automated equipment will inevitably replace semi-automatic or manual production in the future.

Advantages of dry ice blasting

No chemical residues

No chemical cleaners are used during dry ice blasting and no chemical residues are produced.

Environmental protection

Dry ice cleaning does not produce pollutants and is environmentally friendly.

Waterless cleaning

No water is required, avoiding the problems of moisture and water stains caused by using water.

No disassembly required

There is no need to disassemble the equipment or machine and it can be cleaned on site.

Fast and efficient

The cleaning speed is fast, which can save time and labor costs.

Non-destructive cleaning

Cleaning will not cause damage to the surface and is suitable for occasions with high surface requirements.

Versatile Applications

Works on a variety of different types of surfaces and devices, including metals, plastics and other materials.

Non-toxic and non-conductive

Dry ice is a food-grade medium and safe for commercial use. and non-conductive

Non-conductive

Dry ice blasting is non-conductive, making it suitable for cleaning electronic equipment and sensitive electrical components without damaging them.

Eliminate bacteria

The high and low temperature difference and high speed of dry ice blasting can effectively eliminate bacteria and microorganisms, and have a sterilizing effect.

No residual odor

Dry ice contains no additives. It does not add any odorous substances to the object during the cleaning process and does not leave any residue.

Can reduce maintenance costs

Due to the good effect of dry ice cleaning, the maintenance costs of equipment can be reduced and the service life of equipment can be extended.

Dry Ice Blast Demonstration Guide

1.Filling the dry ice pellets: Load the dry ice pellets into the dry ice blaster's supply to ensure that the equipment can continuously supply dry ice pellets.

2.Adjust injection parameters: Adjust the injection parameters of the jet machine as needed, including injection pressure, nozzle angle and injection distance, etc., to ensure the best cleaning effect.

3.To perform cleaning: Aim the nozzle at the surface to be cleaned and start the jet to start cleaning. Make sure the spray direction and distance are appropriate for ideal cleaning results.

4.Display effect: Observe the cleaning process and demonstrate the cleaning effect of dry ice blasting. Surface conditions before and after cleaning can be compared to demonstrate the significance of the cleaning effect.

How does dry ice blasting compare to other methods?

The unique properties of dry ice blasting make it a more efficient, cost-effective and environmentally sustainable cleaning solution than other general cleaning methods.

| Cleaning Method | Residue | Corrosive | Disassembly Assembly Equipment | Pollute | Fast and efficient |

|---|---|---|---|---|---|

| Dry ice blasting | No | No | No | No | Yes |

| Water cleaning | Yes | No | Yes | Yes | N/A |

| Laser cleaning | No | No | Yes | Yes | Yes |

| Chemical cleaning | Yes | N/A | Yes | Yes | N/A |

| Manual cleaning | Yes | No | Yes | Yes | N/A |

OLLITAL--'s dry ice blasting technology can be used in a variety of applications

With unparalleled experience, technical excellence and premium support, you get more than just a state-of-the-art dry ice blasting machine; you get the broadest, most comprehensive customer support resources available.

START OWNING THIS TECHNOLOGY NOW !

Contact us today to learn more about our solutions.